R10R: they were there!

Ricardo Henriques and Michel Vianin were among those spearheading the R10R (Réhabilitation Dix Rhône) project. Launched in 2016, this vast alpine project has witnessed the overhaul of one of the giant Grande Dixence’s two penstocks. Reports.

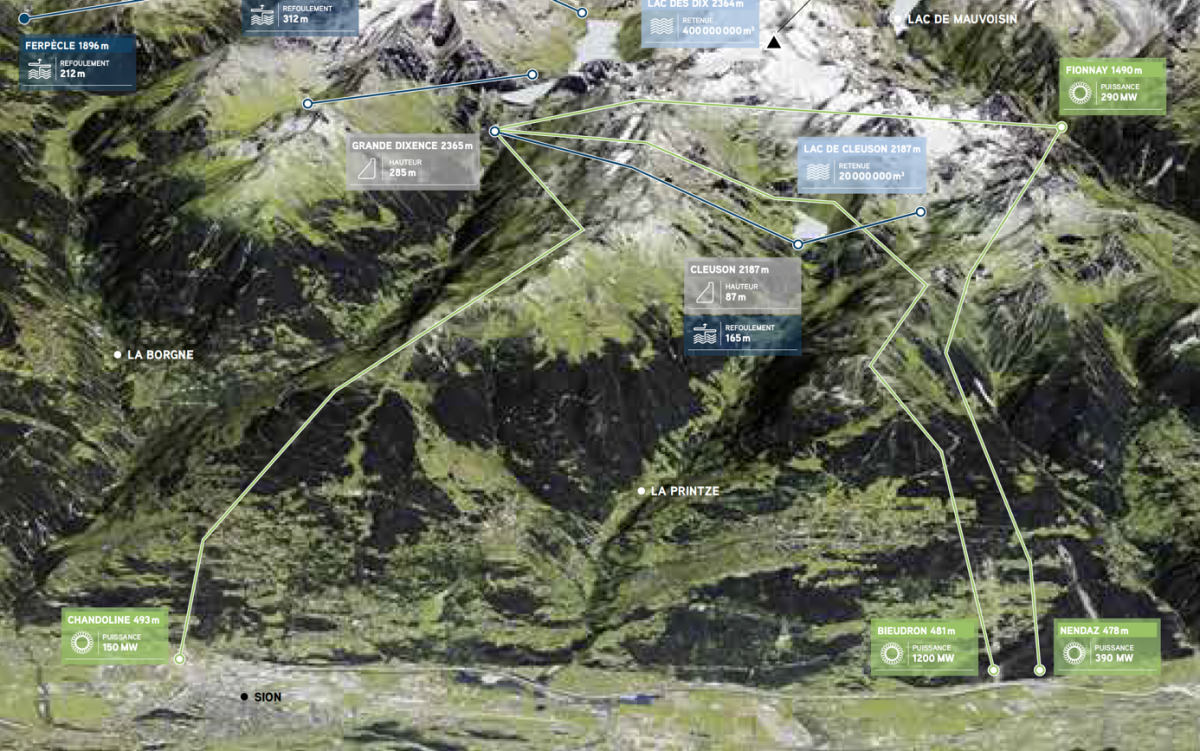

Historically, three penstocks harness the waters of the Grande Dixence dam before they are released into the Rhone. The Chandoline penstock on the far left is no longer in service. R10R has been working on overhauling the one that passes via Fionnay to reach the Nendaz power station in Riddes. (geodata © Swisstopo)

|

The Fionnay-Nendaz penstock The Fionnay power station is one of the three Grande Dixence hydropower

plants. From the dam, a 9 km long tunnel runs at a gentle gradient through the

mountains to bring the water to Louvie, above the village of Fionnay in the

Bagnes valley. At this point, the water plunges down a high-pressure penstock

at a 73% gradient for 1,100 metres to reach six dual Pelton wheel turbines,

which convert this energy into electricity. The water then flows through a new

12 km pipeline to Péroua, 1,000 m above the Nendaz power station. A

high-pressure penstock conveys the water to this facility, which is contained

within the mountain between Riddes and Aproz. Having served its purpose, the

water is then released into the Rhone. The Fionnay and Nendaz hydropower plants

operate in cascade.

|

How would you define your role in this project?

Ricardo Henriques (HRI): I project managed the overhaul of some of the elements that convey the water from the Grande Dixence dam to Fionnay and then to the Nendaz plant: primary and secondary pipes, valves, aeration and so forth.

Michel Vianin (VIM): my role was to manage the renewal, overhaul or reassembly of three 3-metre diameter safety valves that are located at the head of a tunnel or penstock. They play a crucial role: if one were to fail, the entire water supply from the Grande Dixence would stop. The valves have to be failsafe.

What was the toughest challenge?

HRI: having to get on a galloping horse on joining the project in 2020, as I was replacing someone who was leaving. I had been a sales engineer at HYDRO up to that point. Then I inherited the management of the works related to overhauling the corrosion protection of the penstock lining. A real baptism of fire! (Laughs) This type of project is far from easy. What with the tough working conditions and environment for the workers, the zero defect quality specified in the contract and the surprises during project, the project management side of things was very demanding.

VIM: for me, it was having to manage a variable, tight schedule, coupled with the occurrence of lots of unforeseen events. The re-opening was originally scheduled for 1 January 2024, but it could be brought forward by a year. And there were so many surprises, you had to wonder what we had done to annoy an evil spirit!

The highlights?

VIM: I have a whole series of them! The work we did in Louvie, in the Bagnes valley. A survey showed that the valve needed replacing. It weighs over 50 tonnes and has to withstand a pressure of 22 bar. After taking delivery of it on the supplier’s premises, ways had to be found of transporting the various parts to the Louvie underground chamber. This involved building a blondin inclined cableway, and as the area is prone to avalanches, we sometimes had to start them before we could access the site.

HRI: among the surprises, one that impacted the entire site was undoubtedly the discovery of asbestos in samples of old paint at Louvie. Other sectors also contained other toxic and long-banned substances such as lead and PCBs. It meant spending over a year just cleaning up the old pipelines and applying new anti-corrosion coatings that meet current standards.

What are you most proud of, now the venture is over?

HRI: in Louvie, we were dealing with unforeseen circumstances right up to the last minute. Despite this, everyone involved in the various projects carried on working hard and redoubled their efforts so the power generating facility could be brought back on line as soon as possible. As well as demonstrating their high level of skill, colleagues also showed a high degree of commitment and motivation, especially when it came to working over Christmas and New Year. I was very proud to be involved in such a project, and felt enriched by contact with these colleagues.

VIM: the most demanding challenges are also my greatest pride, because we surmounted them. Every time a new problem arose, a solution had to be found quickly. And as someone who spends most of his time in the office, working on site and alongside colleagues in the power stations was a real pleasure. I encountered incredibly skilled and committed people and came away from the project having learned a lot.

Michel Vianin, project lead for the overhaul of the valves, et Ricardo Henriques, project manager, will long remember this major project.

Find out more

Download the brochure describing all the Grande-Dixence installations